Overview of Turbocharging for the Honda S2000

Turbocharging the Honda S2000 can significantly enhance its performance by increasing horsepower. With this modification, the engine’s power output is substantially improved, offering a more exhilarating driving experience. Typically, a turbocharger redirects the engine’s exhaust gases to spin a turbine, compressing incoming air and delivering more oxygen to the combustion chamber. This process results in a horsepower increase and better engine efficiency.

Performance metrics post-turbocharging exhibit impressive gains. Owners have reported boosts in horsepower ranging from 50 to over 100 depending on the turbo kit and engine condition. Alongside the power surge, improved torque and acceleration are also common outcomes, adding to the vehicle’s thrill.

This might interest you : Enhance Your Mini Cooper’s Performance: Mastering Aerodynamics with Front Canard Installation

However, there are common misconceptions surrounding turbocharging. Some believe it drastically decreases engine lifespan, but with proper tuning and maintenance, the turbocharged S2000 can remain reliable. Others fear extensive fuel consumption hikes; yet, when done right, a turbo system can balance power and efficiency effectively.

For the S2000, turbocharging not only amplifies output but reinvents the driving ambiance, making it a sought-after upgrade for enthusiasts demanding higher performance.

In the same genre : Ultimate Off-Road Suspension Kits for Toyota Land Cruiser: Enhance Durability Like Never Before!

Essential Tools and Parts for Installation

Installing a turbocharger on your Honda S2000 requires specific tools and components to ensure a seamless process. First, gather the turbocharger installation tools like a torque wrench, socket set, and screwdrivers. These are vital for precise assembly and disassembly. Additionally, a jack and jack stands are crucial for elevating the vehicle safely.

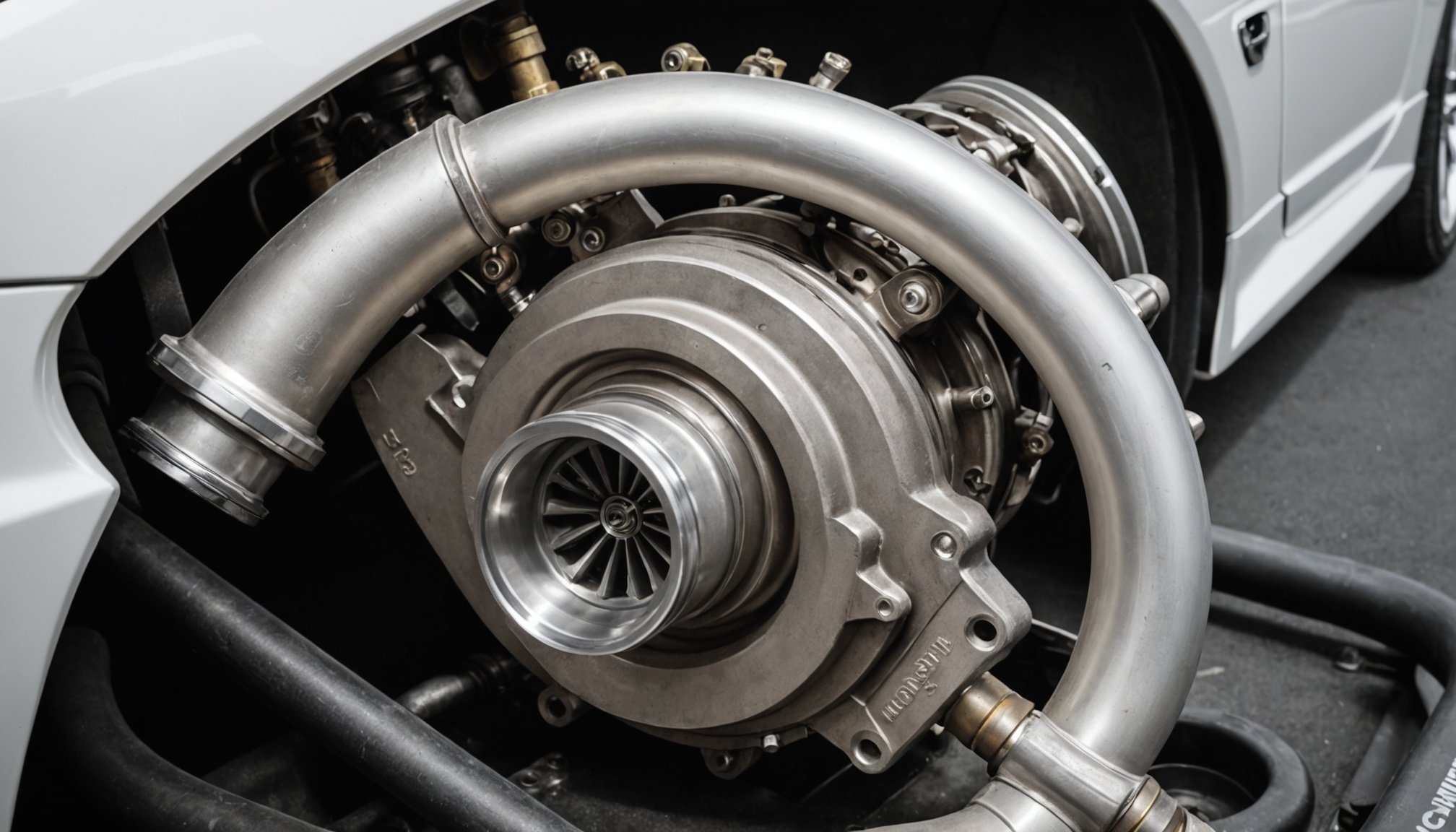

Moving onto the components, a reliable turbocharger kit is the cornerstone of your installation. This kit typically includes a turbo unit, intercooler, piping, and mounting hardware. Choosing a quality kit specifically designed for the S2000 guarantees compatibility and optimal performance. Always opt for kits from reputable manufacturers to mitigate the risk of substandard parts.

Beyond the primary kit, incorporating aftermarket parts such as a high-flow air filter or upgraded fuel injectors can enhance performance. A robust exhaust system is also recommended to handle the increased flow of exhaust gases efficiently.

To achieve the best results, it’s essential to select parts with demonstrated reliability and capacity to endure heightened engine demands. By preparing with the right tools and quality components, your S2000’s turbo installation will be smoother, leading to improved turbocharger performance.

Step-by-Step Turbocharger Installation Instructions

Installing the turbocharger on your Honda S2000 can be a detailed endeavour, but with careful planning and execution, it can be completed successfully. This section provides a turbocharger installation guide to aid enthusiasts in accomplishing this task.

Pre-Installation Preparation

Before diving into the installation, ensure that all turbocharger installation tools and necessary components are ready. Begin by ensuring the vehicle is securely elevated with jack stands. Safety is paramount, so always wear protective gear and verify the stability of the car prior to starting the work.

Removing OEM Components

The initial step includes removing the factory parts to make room for your new S2000 turbo installation. This will typically involve disconnecting the exhaust manifold, intake components, and any interfering bracing structures. Keep track of all bolts and parts removed, as they will be needed later.

Installing the Turbocharger

Begin the process by mounting the turbo unit. Attach it to the exhaust manifold using the supplied gaskets and hardware—ensure all connections are secure. Proceed to install the intercooler and piping, ensuring proper alignment and tight connections to avoid leaks. Finally, hook up the oil feed and return lines, as these are crucial for the turbocharger’s performance and longevity.

Tuning for Optimal Performance Post-Installation

After turbocharging your Honda S2000, proper turbo tuning is crucial to harness its full potential. One essential aspect is ECU tuning. It adjusts the engine control unit to manage the increased power effectively, ensuring peak performance. Immediately addressing ECU tuning guarantees the engine operates safely with the new horsepower increase.

Recommended Tuning Parameters

To optimize, focus on ignition timing, air-fuel ratio, and boost pressure. These adjustments balance performance and reliability. Increased boost must be matched with appropriate fueling to avoid lean conditions, which could damage the engine.

Street Tuning vs. Track Tuning

Street tuning prioritizes a blend of efficiency and performance for everyday driving. Track tuning, however, emphasizes maximum power and responsiveness. It suits competitive scenarios where handling and acceleration are paramount. Decide based on your primary use of the S2000.

To conclude, engaging with an experienced tuner or using specialised equipment affirms that your Honda S2000 turbo system functions at its best. This step not only prevents future issues but also extends engine life, keeping your driving experience exhilarating. Such investment in performance tuning harnesses the true power of your modified vehicle.

Troubleshooting Common Installation Issues

Turbocharger installation on a Honda S2000 can present challenges. Being prepared to troubleshoot common turbo problems is vital. A critical issue to watch is boost leaks. They can stem from improper connections or damaged hoses. Detect leaks by using a pressure test which helps locate loss in boost pressure efficiency.

Another frequent problem is the dreaded turbo lag, where delayed boost response affects performance. To minimize this, ensure the installation of an appropriate turbocharger size compatible with the S2000 is confirmed. Turbo lag can also be mitigated by fine-tuning increased horsepower demands adequately in the ECU.

Unresolved installation missteps may result in oil leaks. Usually, improper oil feed and return line connections or insufficient oil drainage cause these. Verify all lines are correctly sealed and allow unhindered flow. Should the issue persist, inspect the turbocharger for any inner mechanical failures necessitating repair or replacement.

To prevent future complications, always double-check that all bolts and connections are securely fastened. Adhering to a detailed installation checklist prevents common pitfalls, ensuring your Honda S2000’s turbocharging yields improved performance metrics without consequent inconveniences.

Long-term Maintenance and Care for Turbocharged S2000

Turbo maintenance is crucial for ensuring the longevity and performance of a turbocharged Honda S2000. Regular routines are vital to prevent issues and sustain engine health. One key aspect is frequent oil changes; high-performance engines like the S2000 benefit from enhanced lubrication. Opt for premium synthetic oils that can withstand higher temperatures.

Monitoring for signs of wear is also essential. Pay attention to any unusual noises, smoke, or drops in engine power, as these could indicate turbocharger wear or failure. Check hoses and connections regularly for leakages or damage, maintaining optimal turbo longevity.

For the Honda S2000 care, inspect the air filter routinely and replace it if necessary. This ensures the engine receives enough clean air, crucial for maximizing performance. Additionally, maintain the coolant system diligently to manage the increased engine temperatures typically associated with turbocharging.

Implementing these best practices consistently helps maintain the turbo system’s integrity. Such proactive measures avert potential complications and preserve the exhilarating driving experience that a turbocharged S2000 offers for enthusiasts. Maintaining detailed service records further streamlines the process of identifying patterns or recurring issues, ensuring reliability and enhanced performance.